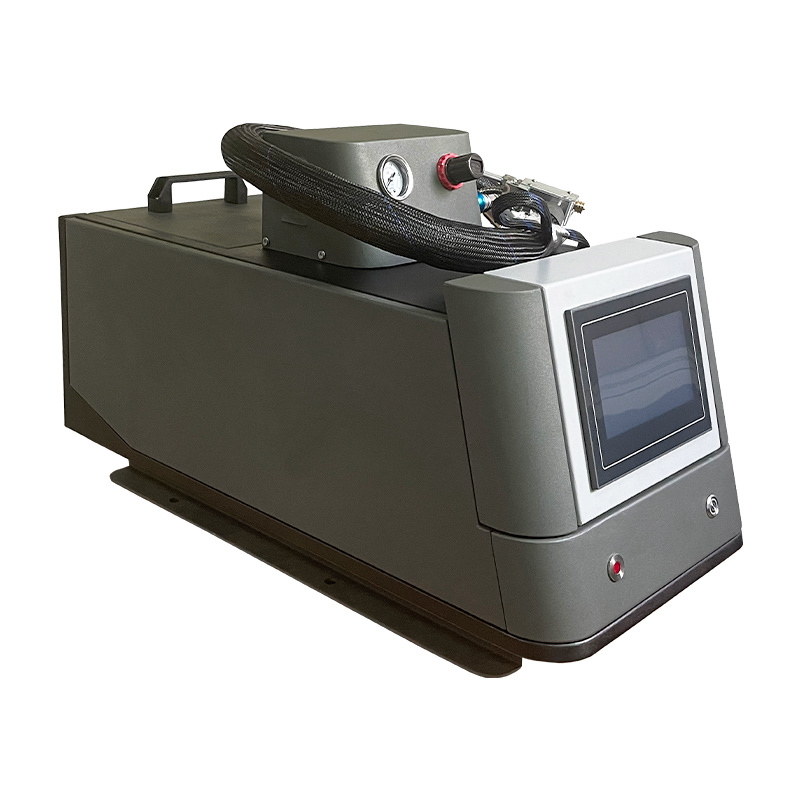

Hot melt adhesive dispensing machine

Functional Features

1. The short circuit of the equipment will automatically cut off power, and the abnormal temperature will automatically stop the heating plug. Poor contact or no plug will give an alarm to prompt the problem point; The glue spitting speed and glue spitting time can be set by parameters.

2. The temperature resistance limit of the whole system is 230 ℃ C; The time required from room temperature to set temperature is 30~45 minutes (there are certain changes according to the ambient temperature)

3. The shooting time of the spray gun is 2.5 milliseconds. Turn off the gun for 1 millisecond: it can be switched on and off 280 times per second. The amount of glue produced is stable and does not leak glue.

4, spray gun can choose zero drip or spray point special gun two kinds; The shooting time of the spray gun is 2.5 milliseconds, and the gun is turned off for 1 millisecond. It can be switched on and off 280 times per second, with stable glue output and no glue leakage. Minimum glue spraying point/line: 1.5mm

Scope of Application

- Video Show

- Equipment parameters

- Instructions for use

- Functional features

-

- Commodity name: Hot melt adhesive dispensing machine

- 应用: Packaging, plastic, wood, metal, etc

- 首页功能特点: 1. The short circuit of the equipment will automatically cut off power, and the abnormal temperature will automatically stop the heating plug. Poor contact or no plug will give an alarm to prompt the problem point; The glue spitting speed and glue spitting time can be set by parameters. 2. The temperature resistance limit of the whole system is 230 ℃ C; The time required from room temperature to set temperature is 30~45 minutes (there are certain changes according to the ambient temperature) 3. The shooting time of the spray gun is 2.5 milliseconds. Turn off the gun for 1 millisecond: it can be switched on and off 280 times per second. The amount of glue produced is stable and does not leak glue. 4, spray gun can choose zero drip or spray point special gun two kinds; The shooting time of the spray gun is 2.5 milliseconds, and the gun is turned off for 1 millisecond. It can be switched on and off 280 times per second, with stable glue output and no glue leakage. Minimum glue spraying point/line: 1.5mm

Hot melt glue machine is a kind of dispensing equipment, which is mainly used to melt solid hot melt glue into liquid state, and to coat the melted glue on the products to be bonded by watching the control system and spraying system. This equipment is widely used in modern industrial production and can be used in automobile manufacturing, electronic and electrical manufacturing, food packaging, paper packaging, clothing manufacturing and other fields.

-

Name Parameters Power 2.7KW(W) Model HT-85101 Power supply voltage 220(V) air source 0.5mpa Spit out time adjustment 1(S) Spit out frequency 16800 (times/min) -

Hot melt glue machine is a kind of dispensing equipment, which is mainly used to melt solid hot melt glue into liquid state, and to coat the melted glue on the products to be bonded by watching the control system and spraying system. This equipment is widely used in modern industrial production and can be used in automobile manufacturing, electronic and electrical manufacturing, food packaging, paper packaging, clothing manufacturing and other fields.

The main function of the hot melt adhesive machine is to achieve material bonding, and its core components include the glue pump cylinder and the control system. According to the working principle and usage scenario, the hot melt adhesive machine can be divided into manual, automatic, desktop and panel types. The automatic hot melt glue machine adopts automatic control technology, which can automatically adjust parameters such as temperature, glue spraying speed and spraying pressure to achieve more efficient and stable operation.

In addition, the hot melt adhesive machine can also choose different coating methods according to different application requirements, such as dot, strip, mist, etc., to adapt to products of different materials and shapes.

-

1. The short circuit of the equipment will automatically cut off power, and the abnormal temperature will automatically stop the heating plug. Poor contact or no plug will give an alarm to prompt the problem point; The glue spitting speed and glue spitting time can be set by parameters.

2. The temperature resistance limit of the whole system is 230 ℃ C; The time required from room temperature to set temperature is 30~45 minutes (there are certain changes according to the ambient temperature)

3. The shooting time of the spray gun is 2.5 milliseconds. Turn off the gun for 1 millisecond: it can be switched on and off 280 times per second. The amount of glue produced is stable and does not leak glue.

4, spray gun can choose zero drip or spray point special gun two kinds; The shooting time of the spray gun is 2.5 milliseconds, and the gun is turned off for 1 millisecond. It can be switched on and off 280 times per second, with stable glue output and no glue leakage. Minimum glue spraying point/line: 1.5mm

Key words:

Hot melt adhesive dispensing machine

National Service Hotline

Holt AutomationTechnical consultant wholeheartedly at your service!

Related Products

The glue filling machine, also known as AB double-liquid glue filling machine and automatic glue dispensing machine, is an automatic machine specially designed for AB double-component glue to be filled on the surface of the product or inside the product, so as to achieve sealing, fixing, waterproof and other functions. Gluing machine equipment is mainly used in the fluid control industry, the application of control glue to potting products and workpieces. The working principle of the glue filling machine is mainly to use compressed air to control the on-off switch of the glue valve, and to use the metering pump to transport the glue from the glue storage barrel to the switch mixing part. The proportioning and metering of A/B glue all adopt high-progress metering pumps and servo motors to achieve accurate proportioning and glue output without being affected by air pressure. The machine automatically and quantitatively perfuses, and the microcomputer controls the glue amount, and the glue amount is uniform and consistent, which solves the phenomenon that the glue amount of each product is inconsistent due to manual gluing and affects the product quality.

The glue filling machine, also known as AB double-liquid glue filling machine and automatic glue dispensing machine, is an automatic machine specially designed for AB double-component glue to be filled on the surface of the product or inside the product, so as to achieve sealing, fixing, waterproof and other functions. Gluing machine equipment is mainly used in the fluid control industry, the application of control glue to potting products and workpieces. The working principle of the glue filling machine is mainly to use compressed air to control the on-off switch of the glue valve, and to use the metering pump to transport the glue from the glue storage barrel to the switch mixing part. The proportioning and metering of A/B glue all adopt high-progress metering pumps and servo motors to achieve accurate proportioning and glue output without being affected by air pressure. The machine automatically and quantitatively perfuses, and the microcomputer controls the glue amount, and the glue amount is uniform and consistent, which solves the phenomenon that the glue amount of each product is inconsistent due to manual gluing and affects the product quality.

The automatic glue filling machine is equipped with a manipulator for automatic filling on the premise of completing the automatic mixing of AB glue, which can automatically pour glue into the products with good arrangement, and realize automatic mixing, automatic mixing and automatic punching of glue and curing agent. The ratio and measurement of A/B glue all adopt high-progress metering pump and motor to achieve accurate ratio and glue output, which is not affected by air pressure. The machine is fully automatic and quantitative perfusion, the amount of glue is controlled by microcomputer, and the amount of glue is uniform, which solves the phenomenon that the amount of glue in each product is inconsistent and affects the quality of the product caused by manual gluing, and improves the original manual production process of customers. Save glue, replace labor, reduce defective products, improve product quality, increase output, reduce production costs, and enhance the competitiveness of enterprises!

Pressure plate dispensing machine, also known as AB double-liquid dispensing machine, is an automatic machine that is specially designed for AB double-component high-viscosity glue to be glued on the surface or inside the product to achieve sealing, fixing, waterproof and other functions. Dispensing machine equipment is mainly used in the fluid control industry, the application of control glue to bond products and workpieces. The working principle of the glue dispenser is mainly to use compressed air to control the on-off switch of the glue valve, and to use the metering pump pressure plate to transport the glue from the glue storage barrel to the switch mixing part. The proportioning and metering of A/B glue all adopt high-progress metering pumps and servo motors to achieve accurate proportioning and glue output without being affected by air pressure. The machine automatically and quantitatively perfuses, and the microcomputer controls the glue amount, and the glue amount is uniform and consistent, which solves the phenomenon that the glue amount of each product is inconsistent due to manual gluing and affects the product quality.

Contact Us

Add.: No. 32 Chenwu Qigu East Road, Houjie Town, Dongguan City, Guangdong Province, China

Follow Us

Copyright© Dongguan Huote Automation Equipment Co., Ltd.