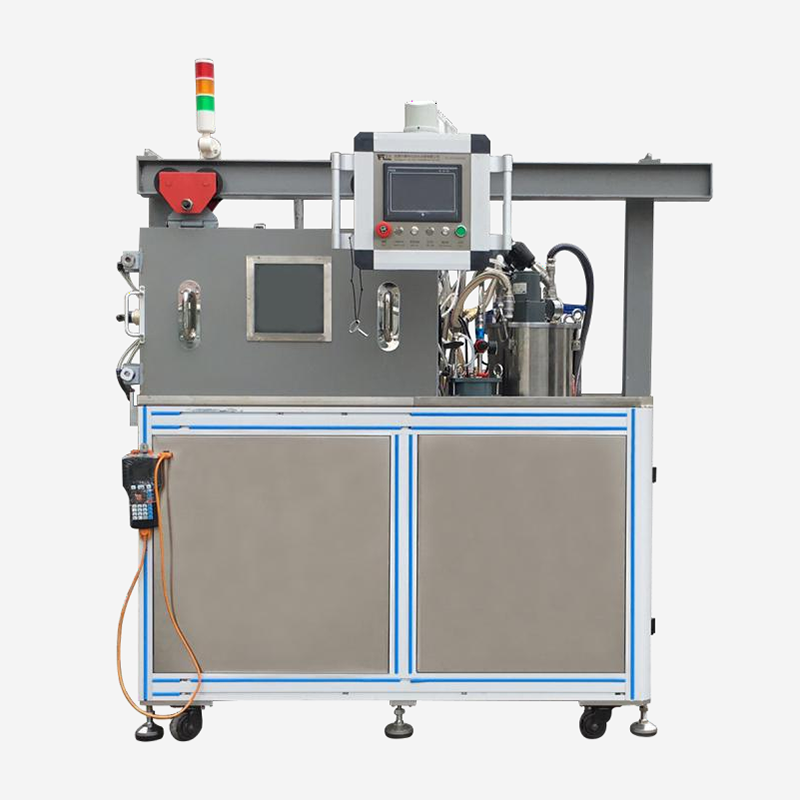

Vacuum glue filling machine Automatic glue filling machine AB glue dispensing machine

Functional Features

1. It has the functions of continuous tween of irregular curves of points, lines, circles and arcs, and can adapt to glue filling of any irregular objects.

2. Fine glue quantity, glue coating speed, glue dispensing time and glue stopping time can be set by parameters.

3. The three functions of glue matching, glue filling and track potting are integrated. Fully automatic operation.

4, according to the need ratio, to achieve mixing side filling glue, maximum saving glue. Double barrel design, A glue and B glue separate storage.

5. Lighting in the box: LED lighting system

6. Vacuum device: flying over the vacuum pump

7. Control system: imported PLC, touch screen

8. Programming method: teaching programming

Scope of Application

- Video Show

- Equipment parameters

- Instructions for use

- Functional features

-

- Commodity name: Vacuum glue filling machine Automatic glue filling machine AB glue dispensing machine

- 应用: Automotive electronics, new energy, transformer glue injection, transformer glue injection, power supply injection, trigger glue injection, igniter glue injection, etc.

- 首页功能特点: 1. It has the functions of continuous tween of irregular curves of points, lines, circles and arcs, and can adapt to glue filling of any irregular objects. 2. Fine glue quantity, glue coating speed, glue dispensing time and glue stopping time can be set by parameters. 3. The three functions of glue matching, glue filling and track potting are integrated. Fully automatic operation. 4, according to the need ratio, to achieve mixing side filling glue, maximum saving glue. Double barrel design, A glue and B glue separate storage. 5. Lighting in the box: LED lighting system 6. Vacuum device: flying over the vacuum pump 7. Control system: imported PLC, touch screen 8. Programming method: teaching programming

Vacuum glue filling machine is a kind of equipment for glue filling in vacuum environment. Compared with the ordinary form of glue filling machine, the biggest difference is the vacuum, will directly affect the quality of the product. The main application industries are automobile manufacturing, capacitor coil glue and so on. At the same time, the equipment has a good ability to cycle work, improve the production efficiency. The vacuum glue filling machine can not only realize the automatic mixing of various proportions of glue, but also has a motion control platform, which can walk in a straight line or a three-dimensional path. Among them, the higher end of the three-dimensional path is generally controlled by a computer and is suitable for various types of products.

-

Name Parameters Proportion of glue 1:1-10:1 (adjustable) XYZ Effective Stroke X600 * Y400 * Z100 (can be customized according to the product) Measurement method Servo motor high precision gear/screw metering pump Proportioning accuracy ±1% Gel-out accuracy ± 1%(20g as base) Gel-out speed 1-15g/s Mixed mode Dynamic/static mixing valve Bucket A30L B8L/30L (stainless steel storage barrel) Working mode Pumping first and then pouring, pouring first and then pumping, pouring while pumping Cleaning method One key cleaning -

One. Use process of glue filling machine

1. Check the glue filling area. If there are sundries, tools, etc., be sure to clean up.

2. Check whether the compressed air is within the normal range (5~7kg), whether the power supply meets the requirements, and whether the plug is loose.

3. Turn on the power of the machine, confirm whether the three-color lamp has an alarm prompt, and observe the alarm information on the display screen. Such as: air pressure alarm, AB barrel glue insufficient alarm, pipeline blockage pressure alarm, etc.

4. Before installing the mixing pipe, check whether the AB glue valve acts normally and whether the glue is accurate. If the glue used is different from the previous one, proportional debugging is required.

5. After the mixing tube is installed, test whether the dynamic mixing is normal, and spit out AB glue at the same time to confirm that the mixing tube is full, free of bubbles, and no dripping.

6. Place the product, edit the program or the starting position, and verify whether the three-axis running track meets the requirements.

-

1. It has the functions of continuous tween of irregular curves of points, lines, circles and arcs, and can adapt to glue filling of any irregular objects.

2. Fine glue quantity, glue coating speed, glue dispensing time and glue stopping time can be set by parameters.

3. The three functions of glue matching, glue filling and track potting are integrated. Fully automatic operation.

4, according to the need ratio, to achieve mixing side filling glue, maximum saving glue. Double barrel design, A glue and B glue separate storage.

5. Lighting in the box: LED lighting system

6. Vacuum device: flying over the vacuum pump

7. Control system: imported PLC, touch screen

8. Programming method: teaching programming

Key words:

Vacuum glue filling machine Automatic glue filling machine AB glue dispensing machine

National Service Hotline

Holt AutomationTechnical consultant wholeheartedly at your service!

Related Products

The glue filling machine, also known as AB double-liquid glue filling machine and automatic glue dispensing machine, is an automatic machine specially designed for AB double-component glue to be filled on the surface of the product or inside the product, so as to achieve sealing, fixing, waterproof and other functions. Gluing machine equipment is mainly used in the fluid control industry, the application of control glue to potting products and workpieces. The working principle of the glue filling machine is mainly to use compressed air to control the on-off switch of the glue valve, and to use the metering pump to transport the glue from the glue storage barrel to the switch mixing part. The proportioning and metering of A/B glue all adopt high-progress metering pumps and servo motors to achieve accurate proportioning and glue output without being affected by air pressure. The machine automatically and quantitatively perfuses, and the microcomputer controls the glue amount, and the glue amount is uniform and consistent, which solves the phenomenon that the glue amount of each product is inconsistent due to manual gluing and affects the product quality.

The glue filling machine, also known as AB double-liquid glue filling machine and automatic glue dispensing machine, is an automatic machine specially designed for AB double-component glue to be filled on the surface of the product or inside the product, so as to achieve sealing, fixing, waterproof and other functions. Gluing machine equipment is mainly used in the fluid control industry, the application of control glue to potting products and workpieces. The working principle of the glue filling machine is mainly to use compressed air to control the on-off switch of the glue valve, and to use the metering pump to transport the glue from the glue storage barrel to the switch mixing part. The proportioning and metering of A/B glue all adopt high-progress metering pumps and servo motors to achieve accurate proportioning and glue output without being affected by air pressure. The machine automatically and quantitatively perfuses, and the microcomputer controls the glue amount, and the glue amount is uniform and consistent, which solves the phenomenon that the glue amount of each product is inconsistent due to manual gluing and affects the product quality.

The automatic glue filling machine is equipped with a manipulator for automatic filling on the premise of completing the automatic mixing of AB glue, which can automatically pour glue into the products with good arrangement, and realize automatic mixing, automatic mixing and automatic punching of glue and curing agent. The ratio and measurement of A/B glue all adopt high-progress metering pump and motor to achieve accurate ratio and glue output, which is not affected by air pressure. The machine is fully automatic and quantitative perfusion, the amount of glue is controlled by microcomputer, and the amount of glue is uniform, which solves the phenomenon that the amount of glue in each product is inconsistent and affects the quality of the product caused by manual gluing, and improves the original manual production process of customers. Save glue, replace labor, reduce defective products, improve product quality, increase output, reduce production costs, and enhance the competitiveness of enterprises!

Pressure plate dispensing machine, also known as AB double-liquid dispensing machine, is an automatic machine that is specially designed for AB double-component high-viscosity glue to be glued on the surface or inside the product to achieve sealing, fixing, waterproof and other functions. Dispensing machine equipment is mainly used in the fluid control industry, the application of control glue to bond products and workpieces. The working principle of the glue dispenser is mainly to use compressed air to control the on-off switch of the glue valve, and to use the metering pump pressure plate to transport the glue from the glue storage barrel to the switch mixing part. The proportioning and metering of A/B glue all adopt high-progress metering pumps and servo motors to achieve accurate proportioning and glue output without being affected by air pressure. The machine automatically and quantitatively perfuses, and the microcomputer controls the glue amount, and the glue amount is uniform and consistent, which solves the phenomenon that the glue amount of each product is inconsistent due to manual gluing and affects the product quality.

Contact Us

Add.: No. 32 Chenwu Qigu East Road, Houjie Town, Dongguan City, Guangdong Province, China

Follow Us

Copyright© Dongguan Huote Automation Equipment Co., Ltd.